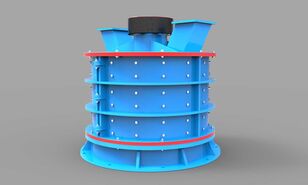

New Hydraulic Sand Crusher 1000*1000 sand making machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

China

China

Model: 1000×1000

Inlet Size: 1000×350mm

Feeding Size: <180mm

Output Size: 0-10mm

Discharge Mouth Controllable Range: 5-50mm

Motor Power: 55kw

Weight: 10.5t

Hydraulic Sand Crusher takes one-time sand making process, eliminates the need for material return, offering high cost-effectiveness, large production capacity, and long hammerhead lifespan. The investment in fine crushers is 35%-50% lower than that of traditional equipment of the same scale. It is widely applicable to the fine crushing of various minerals such as granite, basalt, limestone, river pebbles, cement clinker, quartz, iron ore, and bauxite.

The hydraulic sand crusher boasts stable and reliable operation, producing small, uniform particle size, high production capacity, long hammer life, low power consumption, and simplifies the process by reducing tertiary crushing to secondary crushing. It features a simple structure, convenient maintenance, and sand-making and shaping functions. Its stable operation produces cubic sand that meets national infrastructure requirements. The third-generation sand making machine is a new generation of energy-saving equipment. The open-type sand making machine requires less investment than traditional equipment of the same scale, while offering higher output efficiency. Long-term operating and maintenance costs are also lower than traditional equipment of the same scale. It is widely used in the production of aggregates for manufactured sand and gravel, high-grade highways, railways, water conservancy, airports, construction, cement, refractory materials, metallurgy, and other industries.

The hydraulic open-type sand making machine, based on the original sand making machine design, adds a complete hydraulic open-type system. One-button opening of the rear cover facilitates hammer and liner replacement, quickly resolving customer concerns about material blockage.

1. One-button opening and closing of the back cover takes only 5 minutes, saving approximately 3-4 hours compared to traditional equipment, thus saving time and labor;

2. Afraid of material blockage? After opening the cover in 5 minutes, the blockage can be dealt with directly, with the entire process taking only 10 minutes.

Hydraulic Sand Crusher Other Models:

PXJ800*400——20-30t/h

PXJ800*600——35-40t/h

PXJ800*800——35-45t/h

PXJ1010*1010——45-55t/h

PXJ1200*1100——80-110t/h

PXJ1200*1200——100-110t/h

PXJ1400*1400——100-150t/h

PXJ1600*1600——170-210t/h

PXJ1800*1800——250-270t/h